Galvanized Steel Floor Deck Cold Roll Forming Mill

Basic Info

Model No.: KYT

Product Description

Galvanized Steel Floor Deck Cold Roll Forming Mill

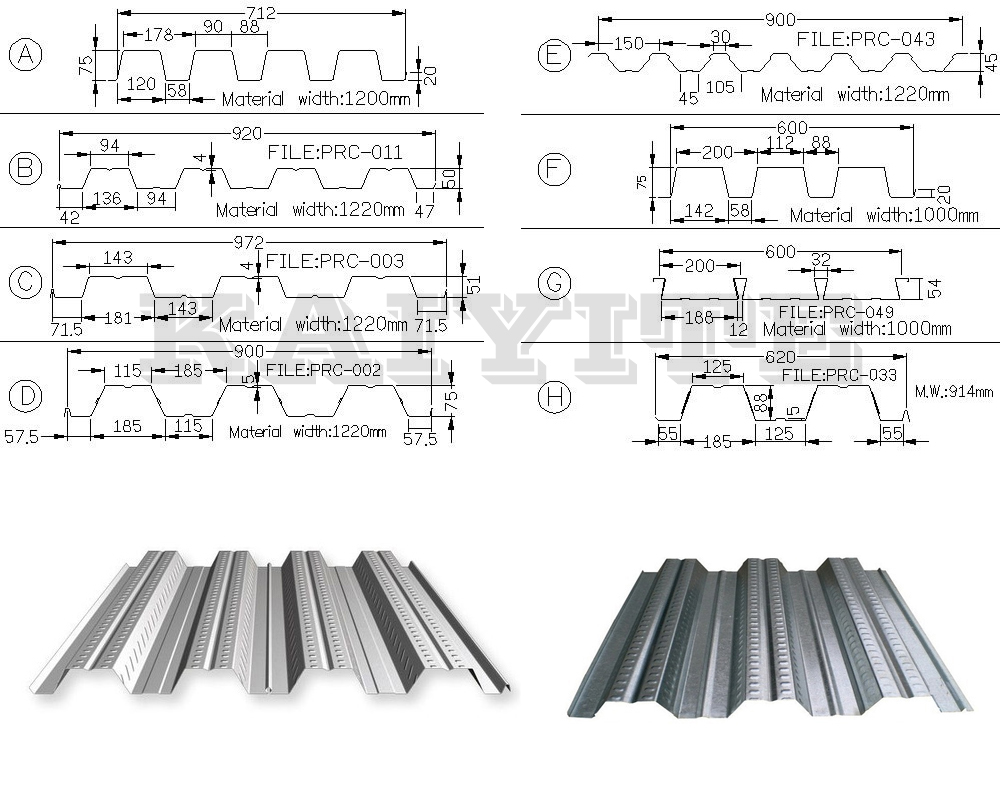

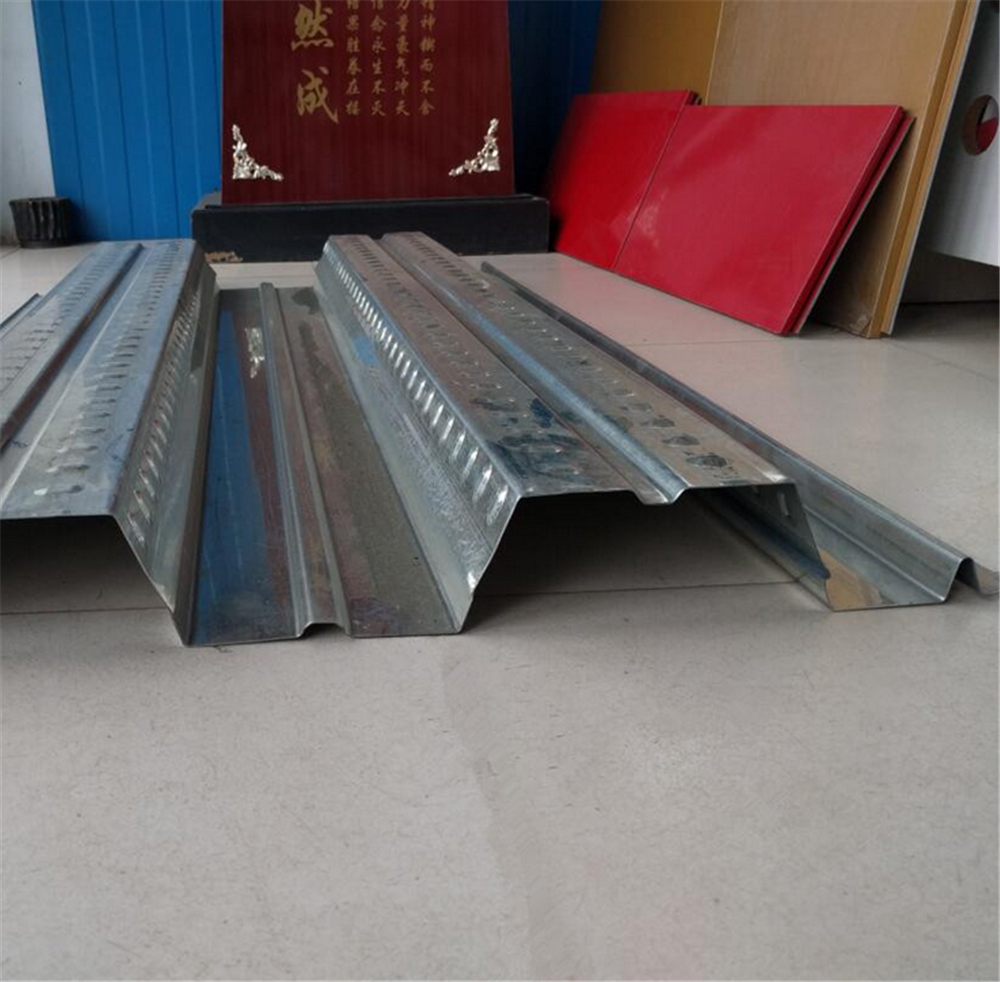

We make our galvanized steel floor deck cold roll forming mill for our Mexico client . Based on the forming method step by step for 720 , we make a advanced design plan . So this floor deck roll forming machine can produce three size panel 720 ,750 ,760 mm with 26 forming steps . This machine can meet client diversified needs .

You can check our machine over all. Not only beautiful in the surface but also good quality.

What is the technical parameters of the floor deck roll forming machine ?

| Raw Material | Raw Material | Galvanized Steel Coil , color Steel Coil |

| Thickness | 0.8-1.2MM | |

| Width of material | 1250 mm | |

| Forming Machine | Frame base | 400H steel |

| Thickness of wall panel | 18mm | |

| Diameter of shaft | 90 mm | |

| Chain | 2" | |

| Main Motor Power | 18.5 KW | |

| Forming Speed | 8-15 meter/min | |

| Forming Steps | 24 rows | |

| Hydraulic cutting system | Hydraulic Power | 5.5 kw |

| Blade Material | Cr12 thickness 30mm | |

| hydraulic pump | Gear wheel pump | |

| PLC | PLC brand | Siemens |

| Machine weight | | 13 ton |

What is the application of the Metal floor decking roll forming machine ?

The equipment production floor board is widely used in power plants, power equipment company, car exhibition hall, steel structure plant, cement warehouse, steel office, airport terminal, sports Venues, large supermarkets, concert halls, theaters, railway stations, logistics centers, Olympic venues and other steel structures.

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including roller shutter door roll forming machine ,door frame machine, roof and wall panel roll forming machine , double layer roll forming machine ,floor deck roll forming machine ,C / Z / U Purlin Roll Forming Machine , stud and track roll forming machine , ridge cap roll forming machine , downspout pipe roll forming machine , shearing machine and bending machine , slitting and cutting machine .

24 hours service the world !

Your kind inquiry or sample are warmly acceptable !

Looking forward to cooperate with your esteemed company !

Let us roll the world , form the future together !

Product Categories : Floor Deck Roll Forming Machine